Add to Cart

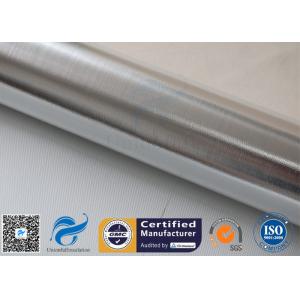

Aluminium Foil Fiberglass Fabric For Reflective Fire Fighter Suits

UPEAL-8732 is one of Unionfull's aluminum foil composite series. It consists of a woven fiberglass fabric 3732(430g/m2) that has been coated with a layer of aluminium foil. The total mass per unit area is 480g/m2. Thickness is 0.43mm.

These base fabric 3732 performs well under temperatures ranging from -100° F to 1022° F. And the glue of aluminiul foil should be used below 1220°F/660℃. However, it does need time for aluminium foil to absorb enough heat to melt, so in fact it can withstand short exposure to higher temperature.

| Product Model | UPEAL-8732 | ||

| Material | Aluminium Foil Fiberglass Fabric | ||

| Weave | Satin Weave | ||

| Yarn Tex | Warp | EC9 33 2X2 | |

| Weft | EC9 33 2X2 | ||

| Total Weight | 480 g/m2 | ||

| Thickness | 0.43 mm | ||

| Thickness Of Aluminium Foil | 7micron/18micron/25micron | ||

| Tensile Strength | Warp | 6000 N/5cm | |

| Weft | 4500 N/5cm | ||

| Width | 100cm | ||

| Service Temperature | Fibre Glass Cloth: 550℃ While mucilage: 300℃ | ||

Features:

Picture:

Aluminium Foil Fiberglass Fabric For Reflective Fire Fighter Suits Images

Application Of These Materials:

The materials provide excellent heat insulation: reflect up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction, convection, and radiation. The side of metalized foil forms an effective barrier against moisture, air currents and vapors. It is economical solutions in many field.

One of the field of aluminum foil coated fiber glass fabric application is fireproof production, such as welding blanket, fire protective blanket/screen/curtain. And used as thermal barrier for protection of the equipment, high temperature protective covers of furnaces, turbines, screens in order to protect them from molten metal splashes/sparks/thermal insulation.